Edgetrim.com Rubber Locking Edge Trim is made of flexible PVC with metal clips. The gripping flanges provide easy installation and secure attachment. Rubber Locking Edge Trim is used for noise deadening, gap filling, and cushioning.

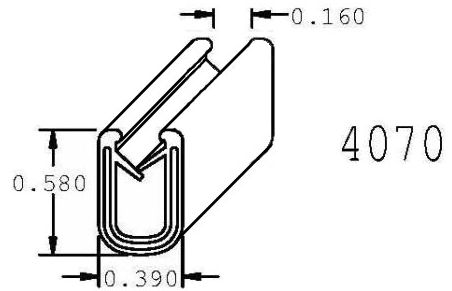

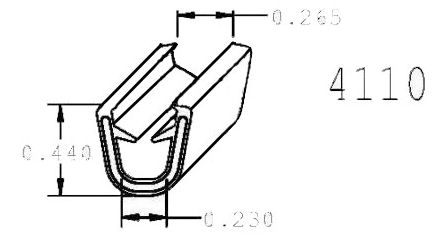

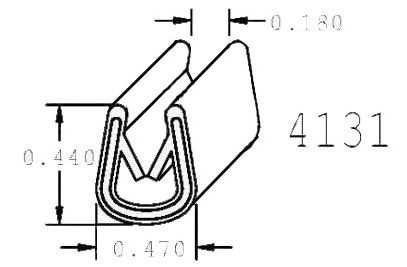

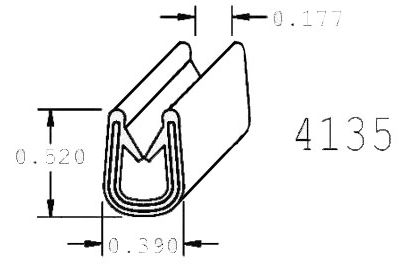

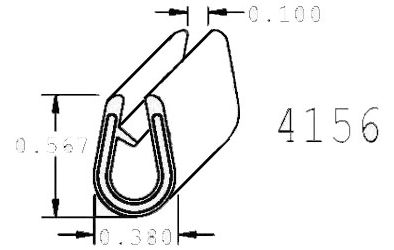

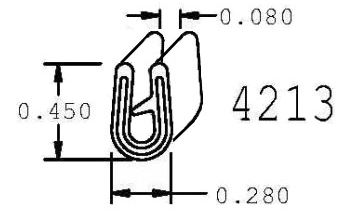

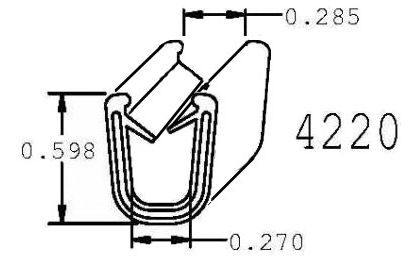

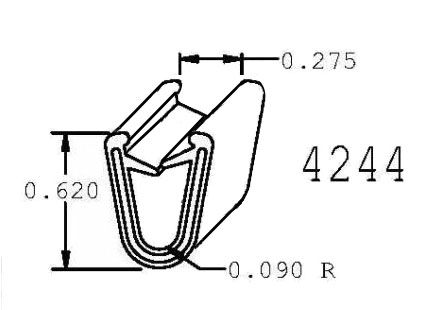

PROFILES

|  |

|  |

|  |

|  |

|

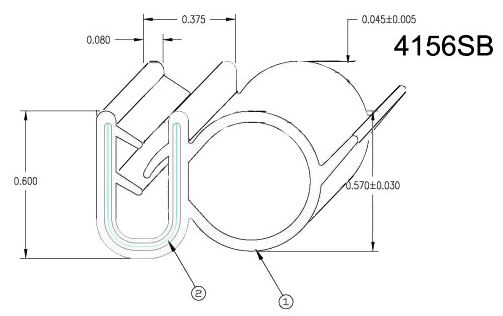

All profiles illustrated are approximately full size and are for reference only.

Rubber Locking Edge Trim

Rubber Locking Edge Trim is constructed of high quality materials that are flexible making them easy to install. At www.edgetrim.com we manufacture Rubber Locking Edge Trim in a variety of sizes and styles. Above, you will find a selection of Rubber Locking Edge Trim that we currently have available.

Rubber Locking Edge Trim temperature rating

The temperature rating for Rubber Locking Edge Trim ranges from minus 20 degrees Fahrenheit to 150 degrees Fahrenheit. This allows the Edge Trim to withstand a wide range of temperature thresholds.

Rubber Locking Edge Trim uses

Rubber Locking Edge Trim is used mainly on various thicknesses of sheet metal, plastic, fiberglass, wood etc.

Specific uses include van doors, boats, boat consoles, forklifts, golf carts, helmets, truck cabs, computer cabinets, tractor cabs, riding mowers, machinery guards, playground equipment, ATV’s, utility trailers, truck bodies etc.

lf a sharp edge is exposed these Rubber Locking Edge Trims will cover the sharp edge and enhance the products appearance. Rubber Locking Edge Trim is a decorative and protective product that is used for noise deadening, gap filling and cushioning.

Edgetrim.com was founded in 1968 to provide the market-place with a reliable source of plastic and rubber extrusions including custom products for the automotive and industrial sectors. Lip trim for spas, car fenders, truck fenders, truck bed covers, camper shells, unfinished edges from Edgetrim.com, manufacturer of trim, gaskets and seals. Edgetrim.com also manufactures fender flare trim, wheel well trim and decorative extruded auto trim.The company has evolved to become a recognized leader in the design and development of automotive, industrial and custom extrusions. Edgetrim.com manufacturing facility utilizes the most modern equipment and materials available to produce a high quality product.Our in-house tool and design facility provides expert engineering from design concept through to the final production of a product. Our plant is staffed with qualified, professional and dedicated employees focused on customer service and product quality. Edgetrim.com was registered to the Quality System Standard ISO 9001:2000 on February 28, 2001.